Values

Customization: We focus on tailoring our machines to our customers’ requirements. We create a solution to meet their specific needs so they can provide the best product to their clients.

Quality: We apply the same demanding quality standards to all processes and services, with utmost attention to detail when designing and manufacturing of the machine you require.

Precision: Pasaban’s machines provide added value, especially in converting processes that require great precision.

Total solution: Offering an all-in-one solution, we can solve the most difficult challenges. We offer comprehensive solutions that include different equipment such as sheeters, winders and ream wrappers.

1928

Pasaban S.A. was founded as a mechanical workshop that repaired and designed auxiliary machines for the paper industry.

- Tolosa (Basque Country, Spain).

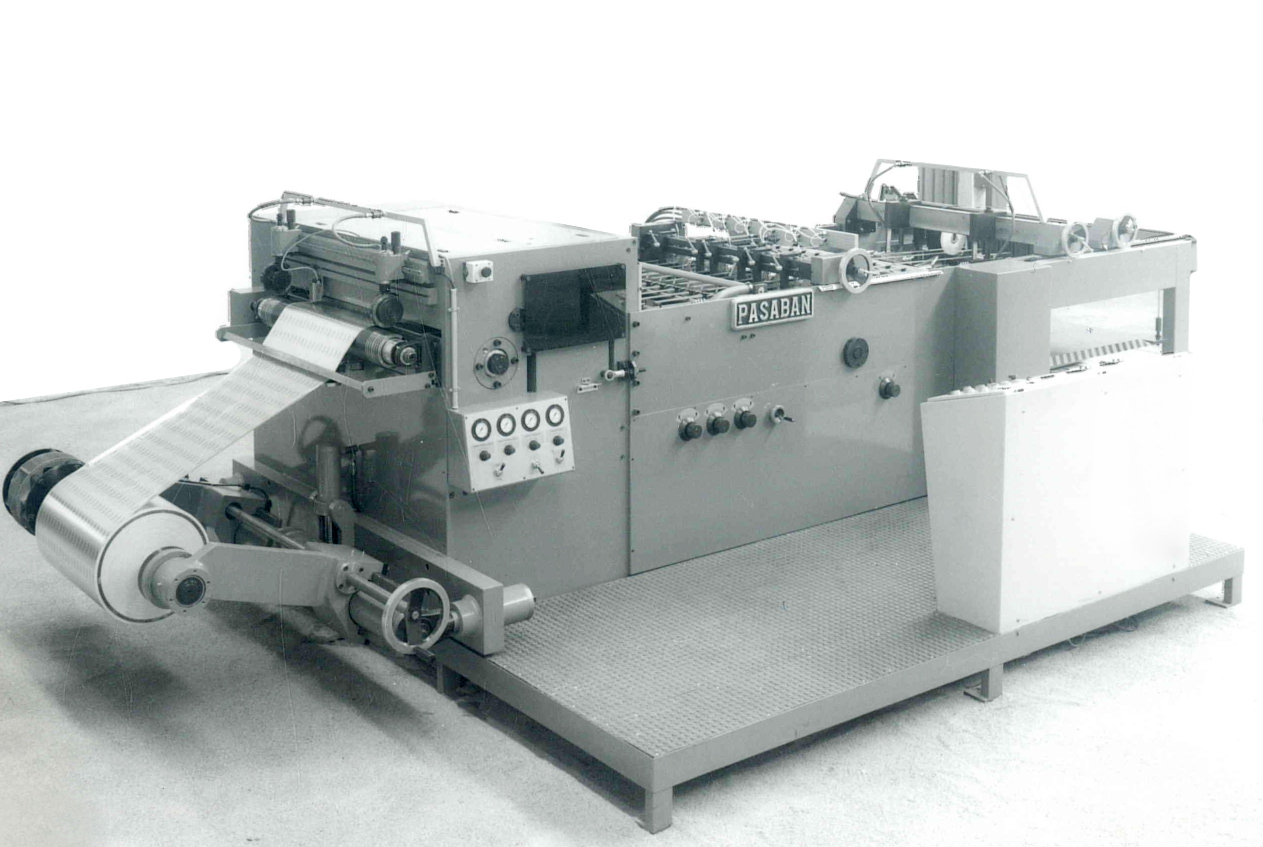

1955

Pasaban specialises in machinery for paper finishing processes.

1977

Pasaban creates its own electronics to add value to the machinery solutions and provide maintenance services that are as efficient as possible.

1983

Pasaban enters the Security Printing sector.

- Security and currency paper winders.

- Double rotary cutting in register sheeting lines.

2004

Pasaban builds a new 3,000 m² workshop to mass produce its hardware.

2008

Pasaban revolutionises the output capacity of banknote sheeters.

- Double width sheeter for banknotes.

2011

Industry pioneers in M2M connection for Preventive Maintenance.

- Pasaban Cloud Connectivity software development.

2012

First patents in the cellulose cutting market.

- Synchro Pulp cutter with double rotary drums with retractable knives.

2013

Pasaban experiences great success with its first machines for adding security features to banknotes and security papers.

- Laser punching system.

- Foil stamping machine.

2014

Pasaban designs novel features for the digital paper industry.

- Automatic ream wrapping machine for special ream heights.

2016

Pasaban rounds out its line of sheeters with the launch of the Compact, designed for mid-volume converters and printers.

2017

Close partnership with the IK4-Tekniker technology centre for ongoing development of equipment.

- New state-of-the-art winder design.

2022

We continue our commitment to innovation.

- Development of an innovative automatic splicing system for foil reels.

- Technological solution for cutting and stacking for the food industry.